Chemical pumps are specially designed to pump dangerous and corrosive chemicals effectively with utmost ease. These pumps are specialized to manage hard to handle chemical fluids and can also handle a wide range of viscosities at high to low temperatures. The discharge pressure of such pumps is up to 170 bars, while viscosity can range from m/HR to m3/HR. These pumps also come with the parts that are capable of self-priming and can also occasionally dry run without any damage. Chemical pumps find their use in chemical and pharmaceutical industry and are very effective to pump the fluid where you cannot use metallic pumps because of the risk of corrosion. These pumps are of various types such as:

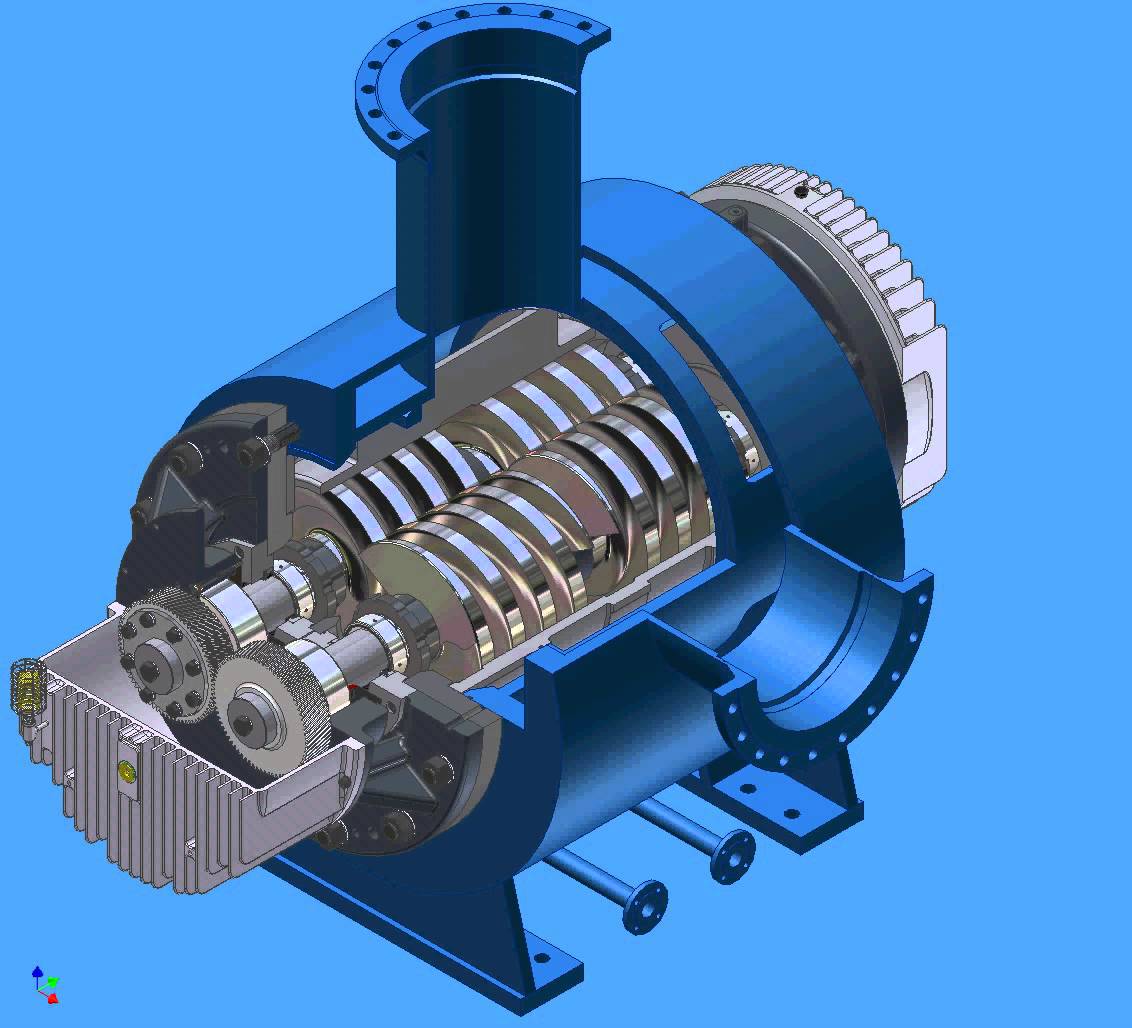

- Twin Screw Pumps

These are positive displacement pumps that come with twin screw. These come with either one or two pairs of screws in the choice of the wetted material. The external gearing drives the screw rotation. During the operation the screws never collide with each other which make them perfectly suited for pumping shear sensitive liquids. These pumps are extensively used in petrochemical industry, chemical industry, oil and gas industry and power plants.

- Thermoplastic Immersible Centrifugal Pumps

These are single stage centrifugal pumps that are designed to be installed in open tanks and sumps. The end of the pump remains immersed in the pump liquid, while the motor region remains on the liquid surface, which make these pumps a perfect choice chemical handling applications where metal pumps cannot be used because of the risk of corrosion. These are not susceptible to stress cracking because they are made of solid block and do not contain injection moulding or welding. All such pumps are made of polypropylene with an option of PVDF, PTFE and HMPE, in order to handle more corrosive liquids with high solid concentrations.

- Air Operated PTFE Tubular Diaphragm Pumps

Popularly known as Codip, these special types of pumps are designed to run for a long time and require minimum maintenance. They self-prime and can safely run dry. Due to these characteristics, they are safe to use under a lot of conditions and also prevent liquid leakage into the atmosphere. When it comes to choices, several different wetted materials are available to you, and the ability of these pneumatic drive pumps with positive displacement reciprocating capabilities make them quite popular.

Chemical pumps serve an important function and are extensively used across various industries. Find a great dealer near you to get them as well!